functionalities required for precise control of any type of equipment or process in a all in one device

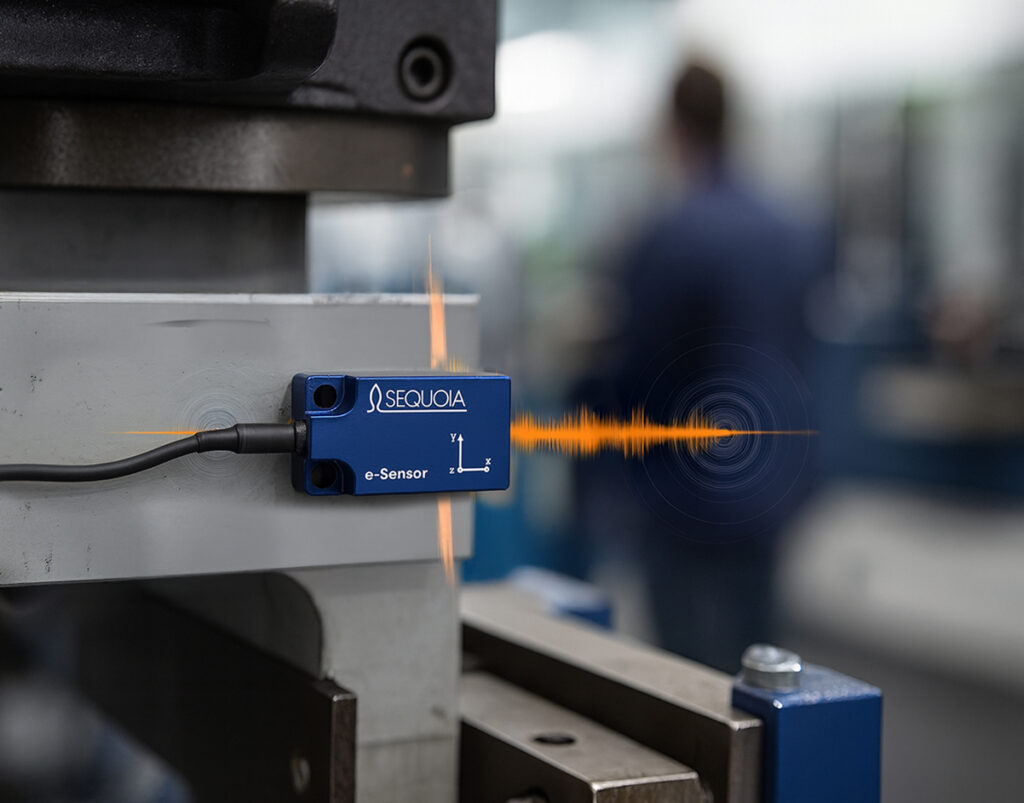

SEQUOIA e-sensor

Innovation is in our DNA

Sequoia transforms your machine tool into a safer, smarter, and more efficient asset.

Reduces downtime and maintenance costs

Black Box and easy Integrations

SEQUOIA e-sensor

Suitable for multiple scenarios

e-sensor Sequoia adapt to a wide range of industrial applications, ensuring reliability, safety, and performance across every stage of production. From vibration and condition monitoring to process optimization and predictive maintenance, our technology provides actionable insights to reduce downtime and maximize efficiency.

Vibration Monitoring

Identifies imbalances and anomalies in rotating machines

Residual Spindle Life

System predicts wear trends to support preventive maintenance and minimize unexpected downtime

Chatter Detection

Prevents tool damage in milling, turning and drilling

Process Monitoring

The interface enables fast detection of anomalies and deviations, ensuring optimal control over production performance.

Condition Monitoring

Tracks bearings, spindles and structural components

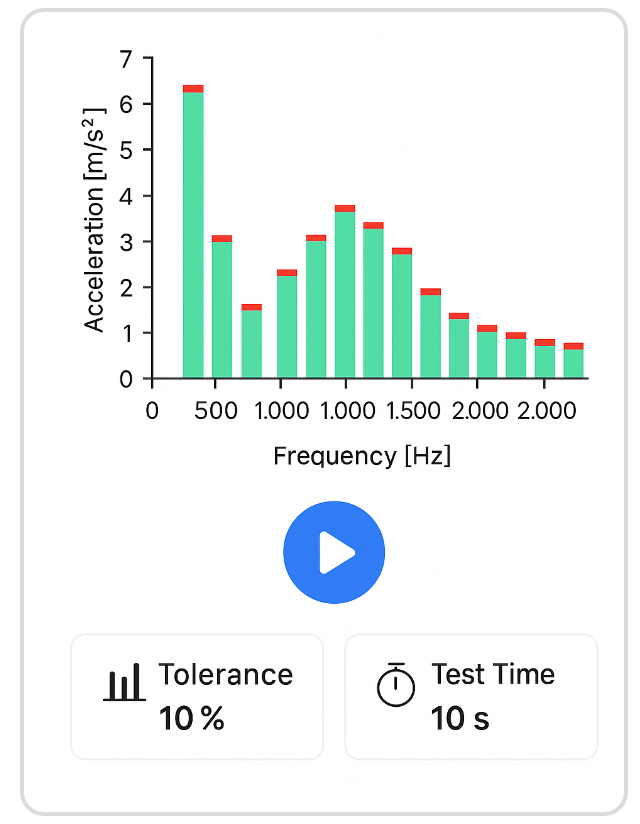

Spectral Analysis

The tool helps identify specific mechanical faults—such as imbalance or misalignment—by isolating characteristic frequency peaks.

Sequoia e-Sensor

Protect your asset with a condition monitoring plan

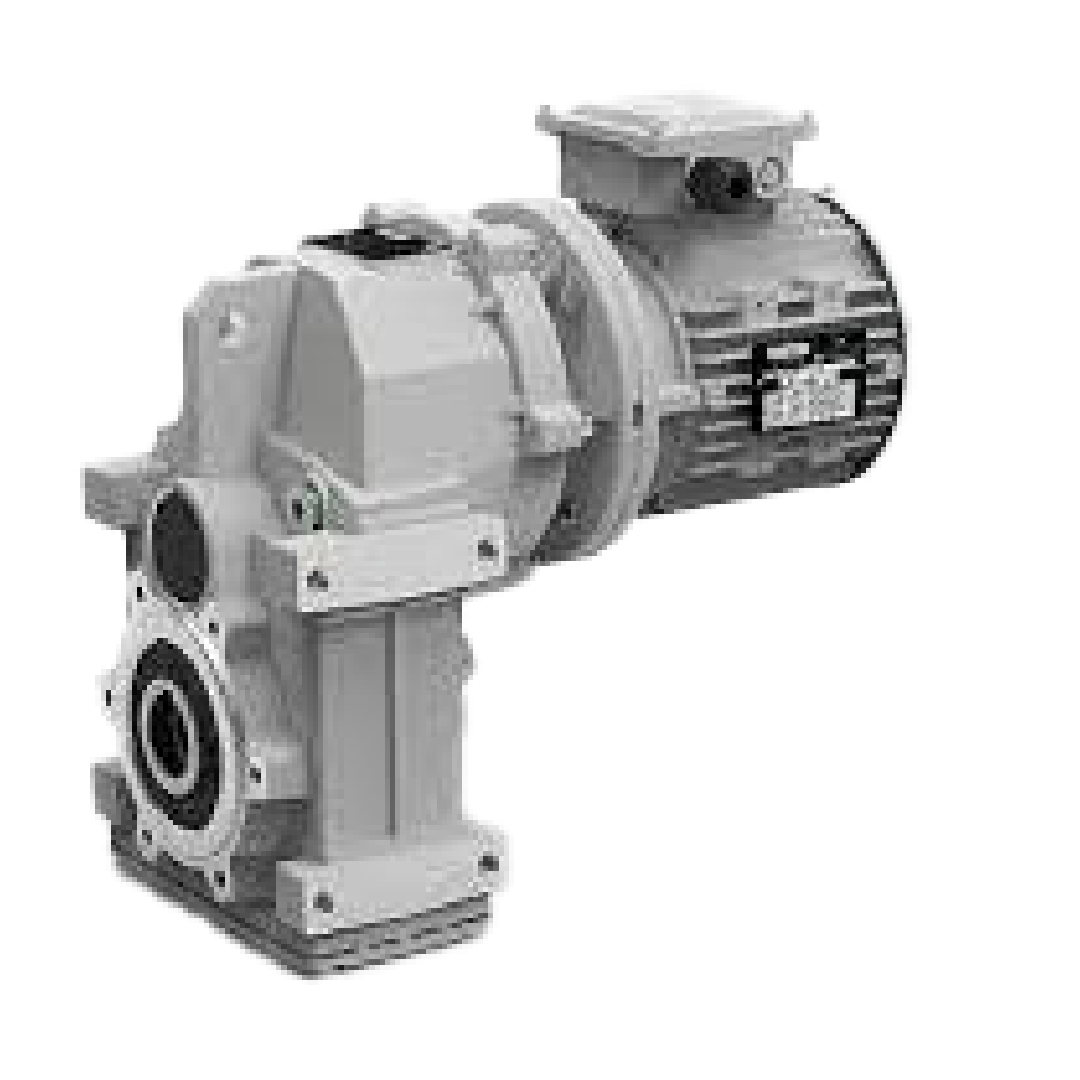

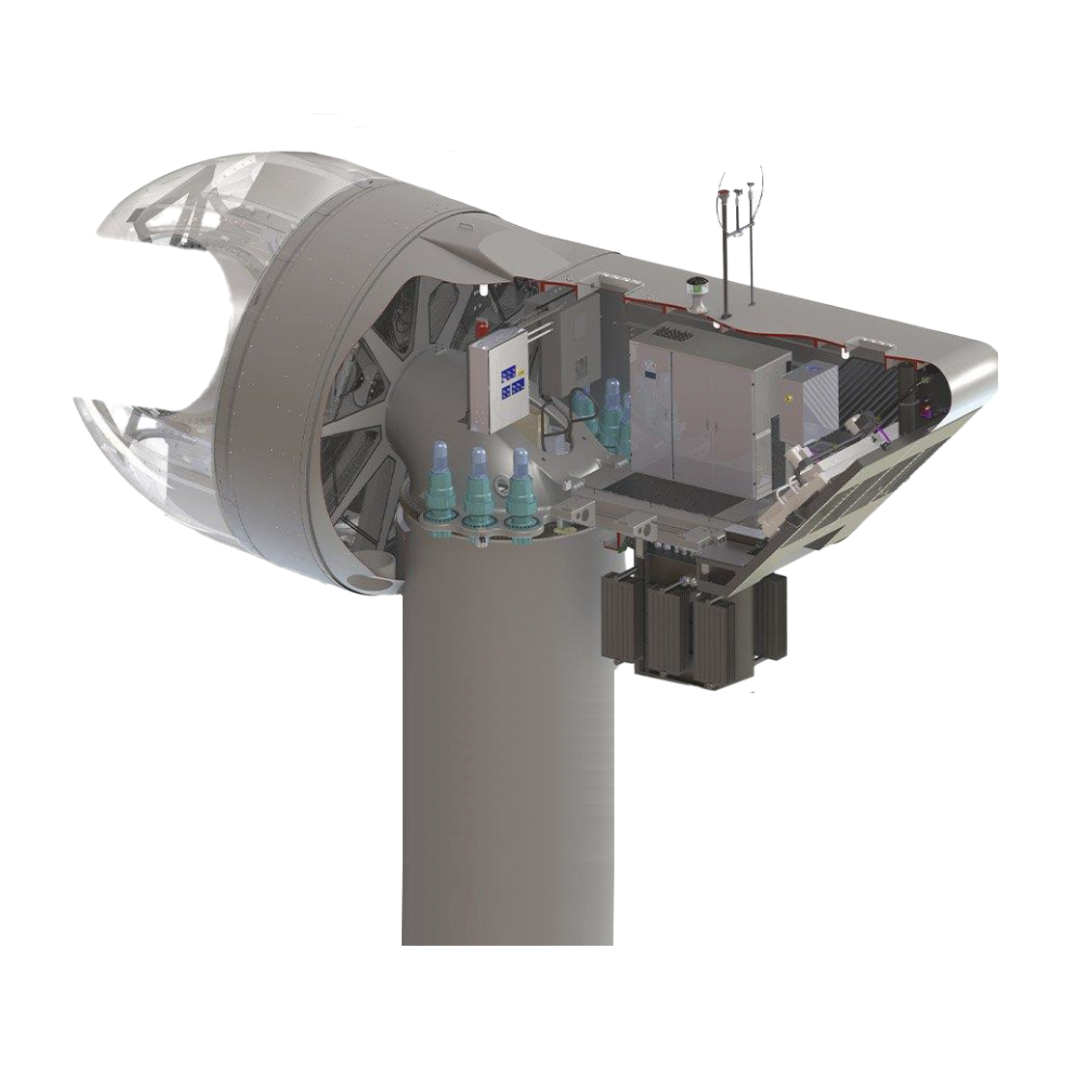

Condition monitoring is the monitoring of machine parts during its operational life.

With the evaluation and study of characteristic values such as vibration, pressure and temperature, it is possible to obtain information on the state of health of pumps, turbines, compressors, motors, gearmotors, blowers, etc.

ELECTRIC MOTORS

GEARMOTOR

WIND POWER

INDUSTRIAL FANS

PUMP & COMPRESSOR

Sequoia e-Sensor

Technical Specification

SEQUOIA e-sensor

Meet the Package for your Business

OEM & MTB

- FREQUENCY ANALYSIS

- SPINDLE WEAR

- BLACK BOX

- RESIDUAL LIFE

- OUTPUT SIGNAL ANALOG/DIGITAL

- COMPATIBILITY WITH SENSORS

END USER

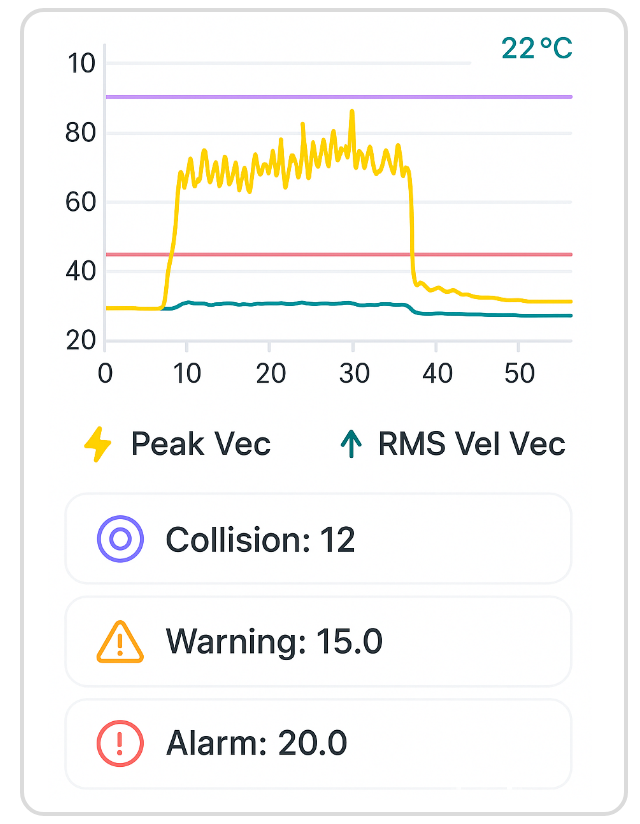

- COLLISION DETECTION

- UNBALANCE

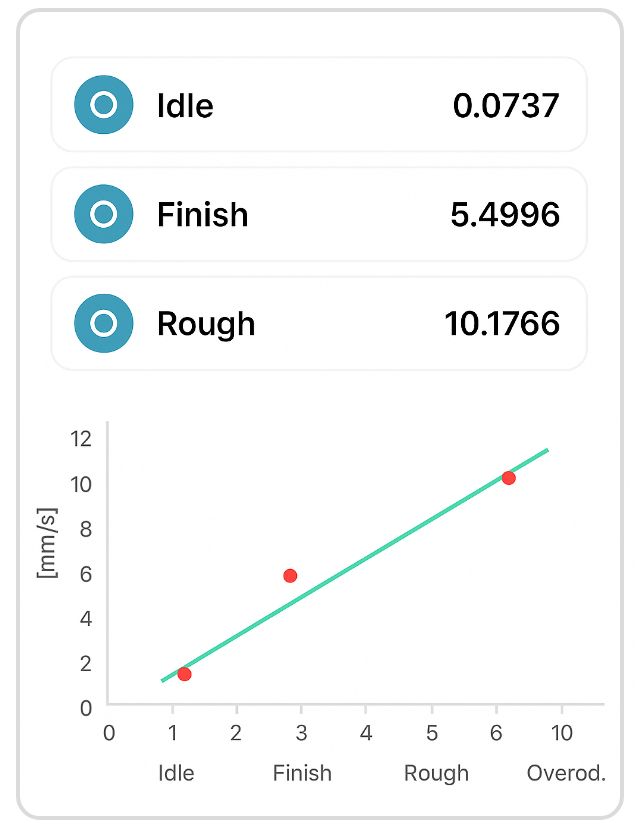

- ADAPTIVE CONTROL

- CHATTER DETECTION

- INTERFACE MIRRORING

- IMPROPER CLUMPING DETECTION

MAINTENANCE

- PREDICTIVE MAINTENANCE

- MACHINE HEALTH

- TEMPERATURE MONITORING

- DETECTION BEARING FAILURE

PLANNING

- ONLINE MONITORING

- PRODUCTION EFFICIENCY

- 16 CUSTOMIZABLE TOOLS SCENARIOS

- CHIP-CUTTING TIME WATCHDOG